Highest quality thermal ash wood for terraces

The thermal ash decking board has a huge advantage, it is the highest quality board, with minimal long-term maintenance. A wonderfully soft surface that does not warp at all even when exposed to weather conditions. Due to its extremely durable properties, thermal ash wood also has its own color, which is very similar to the colors of “Exotic Wood”. In addition, it has no knots and is characterized by a deep, rich shade.

Terrace thermal board

Thermal ash wood for terraces is not only environmentally friendly, but also resistant to woodworm and rot. Thermal ash terrace boards are characterized by stability, sustainability and durability, immunity to environmental factors, withstand large changes in humidity and temperature. Due to the authentic processing technology used, thermal ash terrace boards gain an aesthetic advantage. Thermally treated ash boards are the least likely to crack and warp than other types of boards that are popular in our region.

Thermal ash wood is suitable for many construction projects. Indoors, it can be used for wall or ceiling cladding, floors, and saunas. Outdoors, it is suitable for facades, terraces, and the production of doors and windows.

Origin of thermo ash boards

MDS terasos offers certified thermowood. We are the representatives of the Finnish company HJT in Lithuania.

Manufacturer’s origin: Finland (certified Finotrol-PEFC-COC-1505)

Certified wood: PEFC ST 2002:2013

HJT specializes in the production and further processing of thermally treated wood, aiming to meet consumer needs and adhere to the principles of financially, ecologically and socially sustainable forestry. Reliable quality Finnish production and excellent knowledge of raw materials are the main guarantees of quality in the field of thermal processing of products. HJT is one of the oldest and most experienced thermowood manufacturers in Europe. It is a family business, passed down from generation to generation. Many years of experience, patented production technology and the best raw materials from reliable partners ensure the quality of HJT products.

Thermomodification technology

During heat treatment, the temperature of the wood is first raised above 215 °C, and then returned to normal temperature. The treatment lasts from 1.5 to 3 days and is regulated using hot air and water vapor. The structure of the wood changes, and it is removeds water and extracts such as resin (terpenes). The thermal treatment process changes the structure of the wood, increasing the resistance of the terrace boards to external factors. The reaction to changes in humidity in the environment decreases, regardless of changing weather conditions, the shape of the thermal ash terrace wood remains stable.

The most significant effects of heat treatment on ash wood are: dimensional stability, color darkness, and durability.

Advantages of Finnish-made thermal ash wood

MDS terraces Finnish partners, using only natural methods, thermally modify the highest quality Scandinavian wood, which will last for decades. The most important feature of thermowood boards is dimensional stability, which allows for the creation of reliable construction projects that give spaces a Nordic luxury and naturalness.

Dimensional stability

Smooth thermo ash terrace boards are stable: they do not split, warp, curl or “walk” like other types of wood, such as exotic hardwoods. They perfectly retain their shape, color and softness.

Longevity

The best raw material and non-toxic thermal fashionidentification process makes thermowood ideal construction material even and themselves for the most demanding for projects, ensures products longevity. The properties of thermally treated wood improve as cellulose – a protein – burns out during the treatment process, so thermal ash decking boards do not rot and the deck becomes more durable. This is important in the unstable and rather harsh climate of Lithuania.

Sustainability

Thermowood products made in Finland have been awarded the highest quality PEFC certificates. Sustainability is paramount – from sourcing the wood, responsible production (no chemicals are used in production) to the final product with a long life cycle.

Aesthetics and sensory characteristics

The appeal of thermowood panels also manifests itself through aesthetics and sensory characteristics: natural smell, pleasant tactile sensation and acoustic properties. These advantages of thermowood panels provide opportunities to increase comfort in construction projects. The fact that these boards do not warp and have no ridges is a very important advantage for terrace owners who have children and animals.

Color darkness

Heat treatment improves both the properties and appearance of the wood. Beautiful brown color gives it a stylized image. Thermal ash wood for terraces has a rich brown color, which depends on the temperature during the treatment process – the higher it is, the darker the color.

Quality class

This terrace thermal board belongs to the AB quality class. It is a type of wood that meets high quality standards. Read more in the “Quality Description” section.

Type AB ash decking boards are a mixture of type A and B boards (ratio A – 70%, B – 30%).

If you are looking for stable, high-quality wood for your terrace, choose thermo ash terrace boards.

Processing class

The TermoD wood treatment class means that thermal ash wood is heated to 212°C and is suitable for use in indoor and outdoor applications.

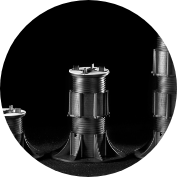

Installation

The MDS terrace expert team recommends installing ash terrace boards using screw foundations, the CAMO invisible fastening system, and A2 and A4 wood screws.

Our customers have already tested and proven mounting systems for this board:

Maintenance

For aesthetic appearance and to maintain the color of the thermal ash terrace boards, we recommend coating the surface with WOCA EXRERIOR OIL oil with pigment (there are 13 colors in the color range, one of which is natural). MDS terraces recommends renewing the terrace boards every year (depending on the operating conditions and the direction of the terrace installation).

Hardwood decking board FAVA Amargosa 21x145x4600

44,69 € / pcs

Hardwood decking board FAVA Amargosa 21x145x4600

44,69 € / pcs

CAMO Drive tool + bag

CAMO Drive tool + bag

Prodeck Premium WPC decking boards

31,86 € – 60,35 € / pcs

Prodeck Premium WPC decking boards

31,86 € – 60,35 € / pcs

Solid larch beam 50x100x6000

43,56 €

Solid larch beam 50x100x6000

43,56 €